Pro Tips for Installing T-Molding (Any Size, Any Shape!)

Over time, the edges of desks, tables, arcade games, shelves, workbenches, and other furniture get worn down or chipped. Instead of buying new furniture, you can replace the edges with plastic or aluminum T-moulding. T-moulding is an extruded shape with a center barb (tang) that gets pressed into the edge to provide impact protection and a nice finished look.

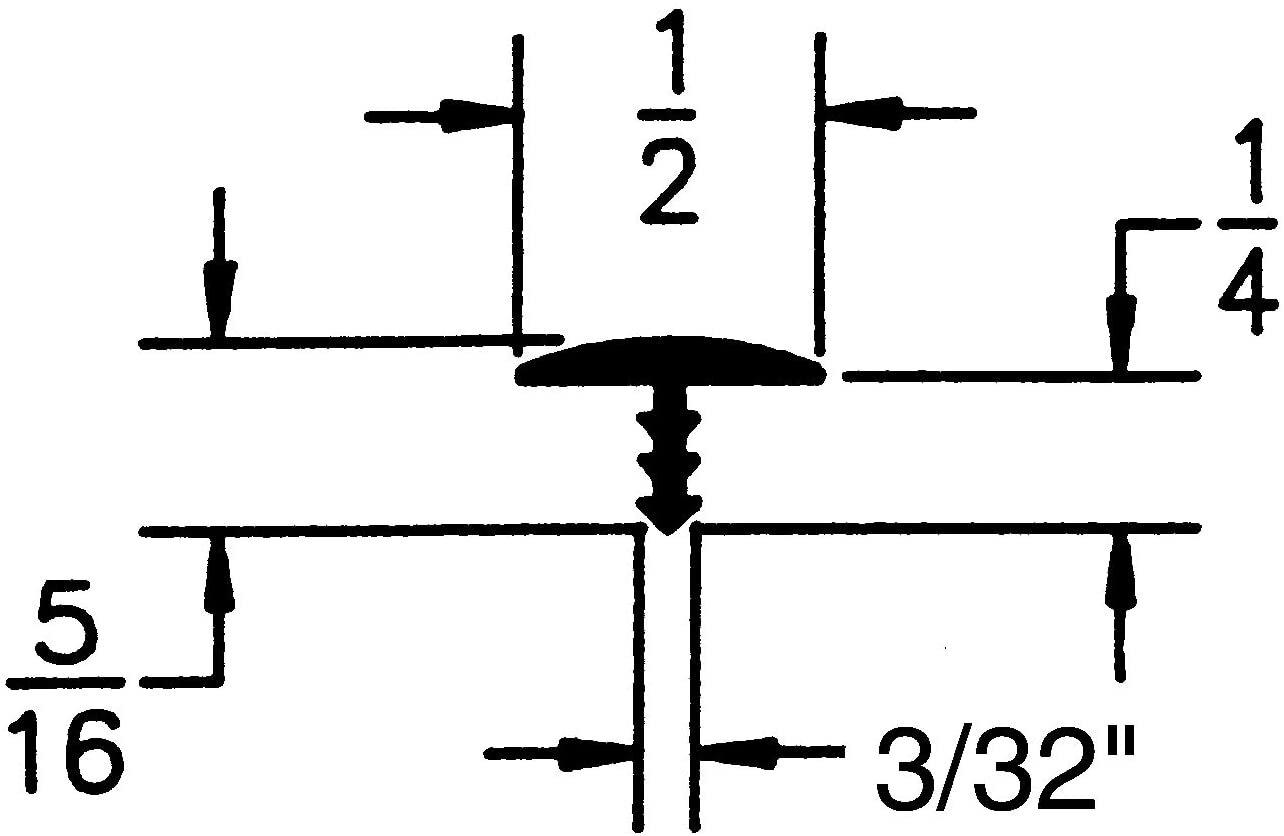

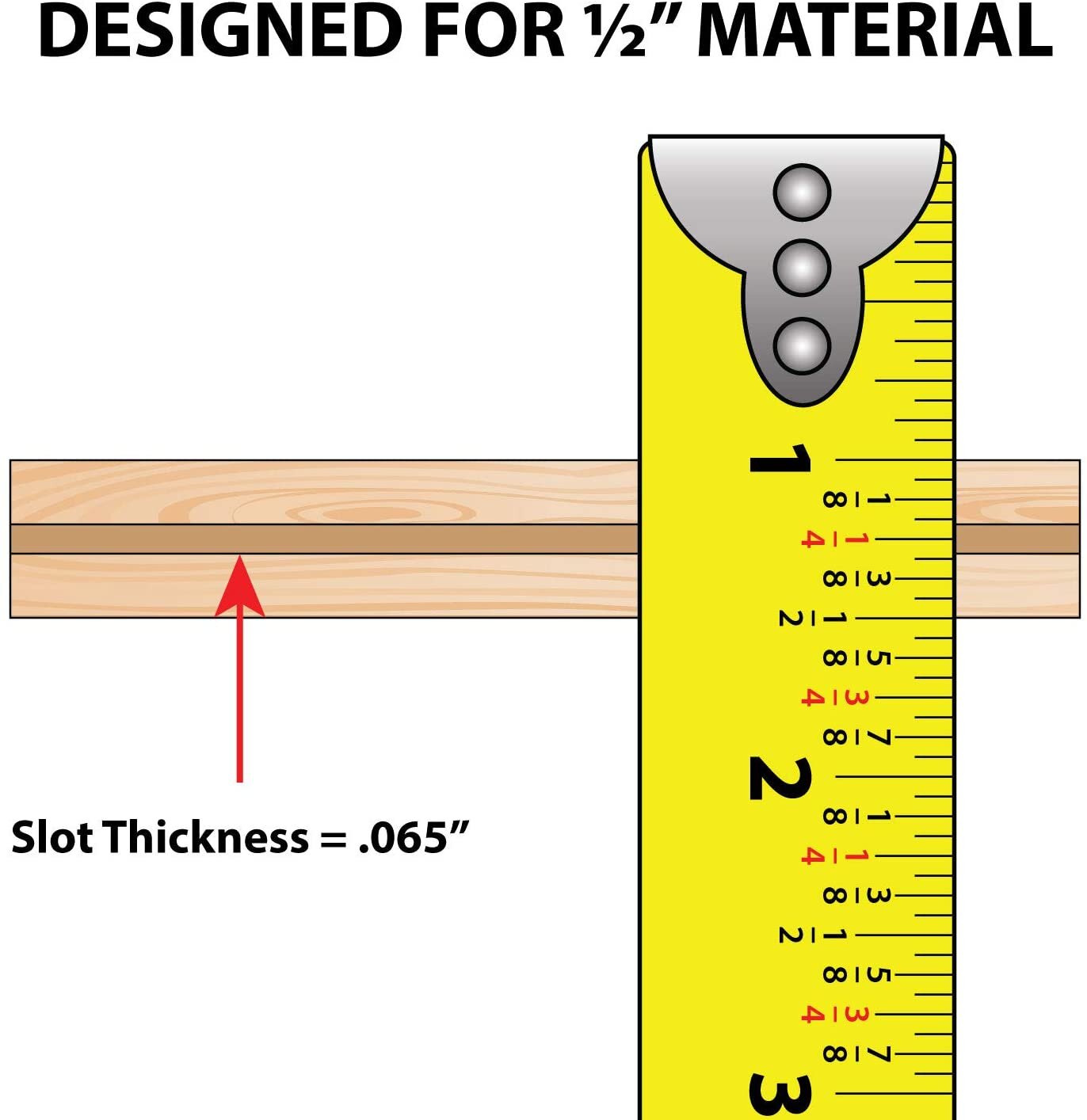

Each T-molding profile has a different sized barb that should fit snugly into the kerf slot so that it cannot be pulled out.

What to Do If Your Replacement T-Moulding is Too Narrow for the Kerf Slot:

If you accidentally purchased Tee moulding with a barb too narrow for your groove, here is a guide to getting a snug fit.

Must-have Tools to Speed Up Installation and Get Professional Results:

The most important "quarter-inch" in mitering is that small portion of the barb that gets removed by the notching tool.

This “R” cut allows the molding to navigate small radii and sharp corners for a clean, smooth application.

This automatic air hammer fits in the palm of your hand and delivers 1,000 blows per minute.

Standard plastic hammer tip can be swapped out for aluminum or steel.

Use a clipper cutting tool to trim the extrusion as needed.

This multipurpose trimmer is tough enough to cut through plastic tubing, rubber, leather, linoleum, nylon, rope, weather stripping, wood trim, carpet, auto-trim, auto belts, and hoses.